Per- and polyfluoroalkyl substances (PFAS) — commonly referred to as “forever chemicals” — are some of the most persistent and difficult contaminants to remove from the environment. Used in thousands of industrial and consumer products, PFAS were engineered for stability and resistance to heat, water, and oil.

“PFAS chemicals are called forever chemicals,” explains JHA Project Engineer Tom Galatro, PE. “They were developed and designed to be stable compounds, which means that they don’t react to many other chemicals. They maintain their properties, which for their intended purposes was desirable.”

Unfortunately, that same chemical stability is what makes PFAS such a serious problem today. They don’t naturally degrade, and once released into the environment, they can persist for decades, contaminating soil, surface water, and groundwater.

“It’s a forever chemical because it doesn’t break down,” says JHA Senior Project Leader Max Stoner, PE. “It stays in its state unless it’s absorbed by carbon filtration or a media that’s designed to remove PFOS. It migrates very quickly and accumulates in the groundwater. And where municipal or private wells draw from that aquifer that’s being contaminated, there is a concern with carcinogens.”

In recent years, PFAS have moved to the forefront of public health discussions. The U.S. Environmental Protection Agency (EPA) and state agencies are enacting increasingly stringent regulations. This is no longer an issue affecting only large cities — smaller communities and noncommunity water systems are now firmly in regulators’ sights.

Travis Long, CEP, VP and Director of Environmental Services at JHA Companies, describes the shift: “The conversations today around forever chemicals or PFOS, PFOA, is a very hot topic as regulations continue to become more stringent. Municipal water systems have been required over the last year to conduct quarterly testing. As we look into 2025, systems serving a population less than 350 are going to be required to do monitoring, and that’s all of our noncommunity systems, convenience stores, things that have public water supplies.”

That means even the smallest municipal or private systems — ones that historically escaped scrutiny — are now facing compliance requirements. Galatro emphasizes that “they’re looking at smaller community sized municipalities that weren’t scrutinized before but are now becoming scrutinized. As operating permits become renewable, and all operating permits are renewable, they will be imposing these regulations to all water suppliers.”

JHA Companies has been at the forefront of PFAS remediation for more than a decade. “We first became involved in addressing PFAS in the water supply system in 2014 during the first round of EPA sampling of water supplies in the nation,” says Galatro.

One of the first systems JHA worked with was a small regional airport in Southern Pennsylvania — the first water system in its DEP regional office to be identified with PFAS contamination. At the time, PFAS was still an unfamiliar term to most water professionals. “In 2014, PFAS was an unknown contaminant,” Galatro recalls, “and there wasn’t a whole lot of experience on removing them from the water supply. Since there wasn’t a lot of historical data or papers published on the removal of PFAS from water systems, we had to go to these manufacturers of these chemicals to find out what they knew. We had to search the technical literature laboratory to identify projects that had started removing PFAS. We identified them. We contacted people. After many discussions, we determined that we were going to pilot test an activated carbon absorption system, and then went on to the next phase, which was to design and install it. But we had to figure out how to develop this plant upgrade and still not miss a day’s worth of water supply to the plant while we were completely tearing this plant apart and putting it back together. We had to actually build the new facility within the footprint of the existing facility. We were able to work as a team, and JHA was able to get this thing done successfully and, without violating a permit and without missing a day’s worth of water supply.”

This innovative, cost-effective approach earned national recognition. “Our Camp Hill team’s success with this project put them in the national spotlight,” Long says, “by being able to implement one of the first-of-its-kind, state-of-the-art processes that identified PFAS treatment and was able to meet the regulatory requirements cost-effectively, really setting precedents for what lies ahead for many, many similar systems.”

PFAS remediation is an expensive undertaking, and securing funding is often one of the biggest hurdles for municipalities. Even well-staffed organizations can find the process overwhelming. “Even though our client had several engineers on staff, they weren’t accustomed to applying for grants and loans for financing water and wastewater projects,” says Stoner. JHA stepped in, helping the client secure a PENNVEST grant — one of the first in the state for PFAS facility upgrades. “JHA has the capabilities of applying for those grants and loans,” Stoner adds. “We know the process, and we’ve done it for multiple projects for decades.”

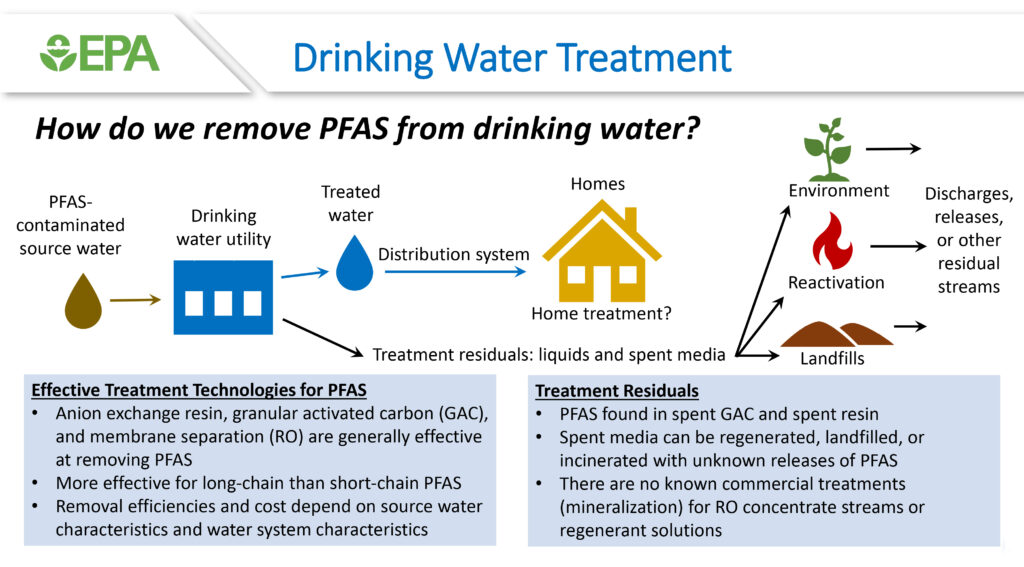

No two PFAS challenges are alike. JHA develops solutions that match each client’s specific needs, budget, and operational capabilities. “JHA can assist municipalities in addressing the PFAS problem in many different ways,” says Galatro. “We have engineers and designers that can determine treatment approaches. JHA has done anything from large facilities that have reverse osmosis that can remove the PFAS to smaller municipalities who don’t have that financial backing or the operational expertise. We have to look at how this is going to be constructed and installed, how it’s going to be operated in the future, and how it’s going to be funded. But we can also look at the regulatory implications and negotiate with the regulatory authorities on the implementation. So, we have to be cognizant of all those options and try and pick the one that fits your particular situation.”

For communities facing potential PFAS contamination, early action is critical. “It’s very important that clients communicate early so that we can plan, as a team,” Long stresses. “The sooner that they can work with a professional, the better that it will be for their compliance attainment and potentially their overall cost effectiveness.”

As PFAS regulations tighten, the challenges will grow — but so will the opportunities for innovative, cost-effective solutions. JHA Companies remains committed to staying ahead of the curve, monitoring emerging technologies, and tackling even the most complex projects. “As we look at the challenging environment ahead of us,” says Long, “specifically with Forever Chemicals, we really take pride in ensuring that we stay current with the regulations. We monitor the most practical alternatives for treatment. And we’re not afraid to tackle the challenging projects.”